SYM ORC-S is an automatic multi-station balancing machine especially designed for balancing operations of armatures, electric motor rotors etc. It works as an automatic balancing machine in measuring and correcting the unbalance of the armatures inside the production line.

Operation Steps

The machine operations are automatic. The operation steps are given below.

- Armature is transferred to the balancing machine by infeed conveyor.

- Lifting apparatus lifts armature from infeed conveyor for loading of gripper robot.

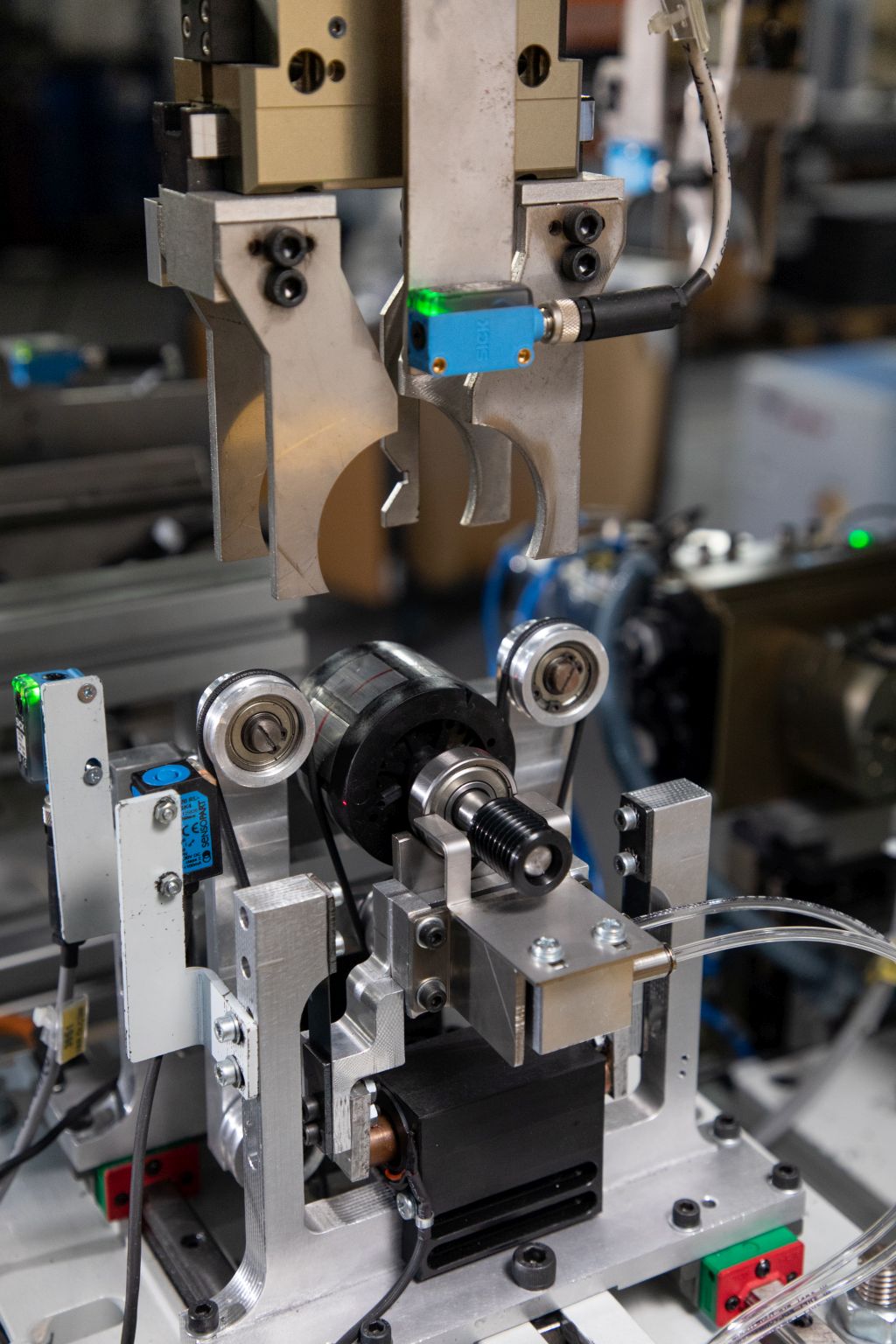

- Gripper robot takes armature from lifting apparatus and loads it to the unbalance measurement station.

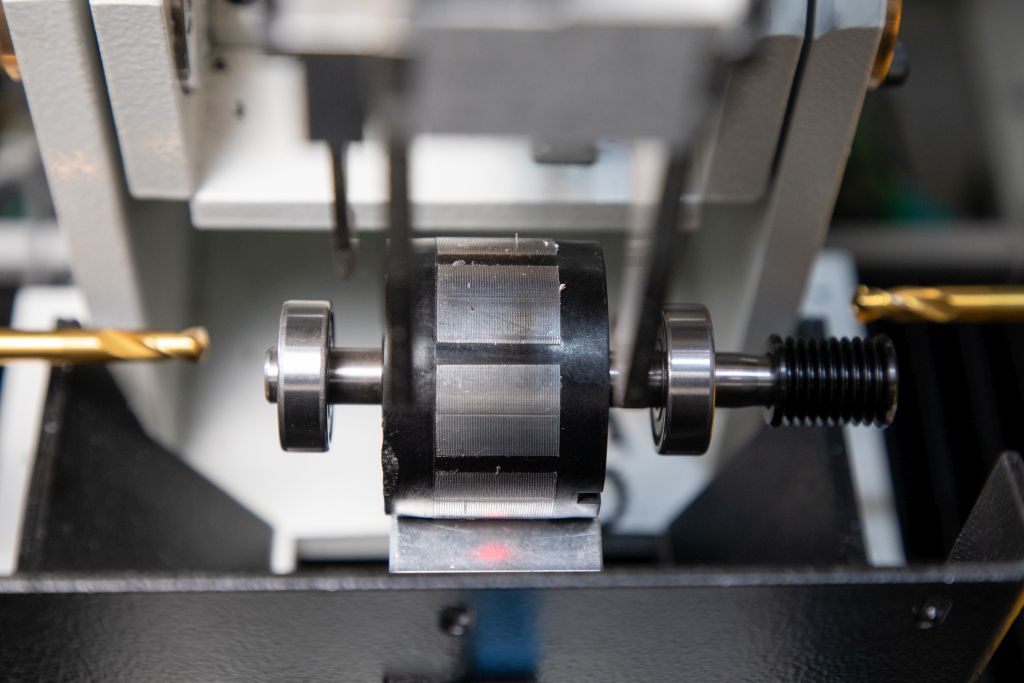

- Armature begins to spin in the unbalance measurement station. Rotation speed, starting, stopping movements are controlled by the speed controller. After the rotation is completed, the unbalance values and positions are automatically displayed on the screen of the control panel. Positioning according to the unbalance points is performed by servo motor automatically.

- Armature is transferred to the 1st unbalance correction station for surface milling operation for 1st plane.

- Unbalance of armature is corrected by milling in the first plane, then gripper robot transfers armature to the 2nd unbalance correction station for surface milling operation for 2nd plane.The chip extraction system which automatically works with milling units, removes chips during milling operation synchronously. During milling operations, armature is fixed with a pneumatic clamps.

- Armature is automatically transferred to the unbalance audit station.

- In unbalance audit station, unbalance of armature after corrections, is measured.

- If measured unbalance value is over the tolerance (maximum permissible unbalance value), the armature is rebalanced after transferring back to the unbalance correction stations.

- If measured unbalance value of armature is within tolerance, armature is automatically transferred to OK outfeed conveyor. (*)

- If measured unbalance value of armature is still over tolerance after rebalance, armature is automatically transferred to NOK outfeed conveyor.

(*) Infeed conveyor and OK outfeed conveyors are one piece and a continuation of each other.

Electronic Measuring Unit & Software

- Automatic Measurement

- Rotor-Specific Reciping

- Tolerance Calculation According to ISO 21940 Standards or Rotor Specific Tolerance Determination

- Reports in Different Formats (.pdf, .xml, etc.)

- Easy-to-use Messmatic Balancing Software

- Determining Software Access Levels (Admin – Chief – Operator, etc.)

- Remote Desktop Connection

- Displaying Balance Measurement Results in Different Units (g.-mg. – g.cm – g.mm – N.mm)

- Up to 90% Unbalancing Correction

- Station 1: Loading and Unloading

- Station 2: Balancing

- Station 3: Drilling in Two Planes

- Station 4: Balance Check Measurement

- Main Motor: Servo Motor

- Balance Measurement Speed: 1.000 – 1.500 rpm/min (Varies according to Rotor Weight)

- Cycle Time: 15 sec. (Varies according to the number of holes)

- Electricity: 380V ± 10 % 50Hz ± 3 %